Jewellery Moulding

Vulcanised Rubber and Cold Silicone Moulding service in the heart of London's historic jewellery district, Hatton Garden.

Vulcanised Rubber and Cold Silicone Moulding Service

Selecting the appropriate mould is a crucial step in the jewellery-making process. A well-chosen mould significantly enhances the quality of your wax model, leading to precision casting results.

At House of Casting, we collaborate closely with our customers to select the most appropriate mould type tailored to their unique requirements. While there are key distinctions between vulcanised rubber moulds and cold silicone moulds, our experienced team of jewellers has mastered the intricate details of this process over the years. Whether you’re working with base metal masters, organic objects, hollow items, or hand-carved waxes, we are dedicated to doing everything possible to achieve the best casting results for you.

Jewellery Moulding: Your Questions Answered

At House of Casting, we’re here to help you achieve the best possible results. If you can’t find the answer you’re looking for, please don’t hesitate to get in touch with our team—we’re always happy to assist.

-

Vulcanised rubber moulds are the most commonly used type in the jewellery-making process. These moulds are created by heating and compressing sheets of rubber, making them particularly effective for base metal masters and other metal objects capable of withstanding high temperatures. Once your master is ready, it is carefully removed from the mould, allowing the remaining material to be passed on to our wax injection team for casting preparation. One of the significant advantages of vulcanised rubber moulds is their minimal shrinkage rate—approximately 1.5-2% from master to mould.

We can help you evaluate how this slight variation may impact your design, ensuring you make an informed decision.

-

Benefits of Vulcanised Rubber Moulds include:

Cost-Effective and Efficient: These moulds are not only budget-friendly but also quick to produce.

Durability: They are designed to last, ensuring consistent quality over time.

High Production Capacity: A single mould can produce approximately 5,000 cast items, maximising output and efficiency.

-

Creating moulds using cold silicone is a more intricate method that involves carefully pouring liquid silicone over and around your master. This approach eliminates the need for heat and pressure, making it ideal for delicate items, 3D-printed plastic pieces, hollow objects, and organic forms like leaves. Additionally, this technique is versatile enough to accommodate unusual masters, including toys, models, and other non-jewellery items.

-

Benefits of Cold Silicone Moulds

No Shrinkage: Cold silicone moulds experience no shrinkage from the master to the mould, meaning you only need to consider casting shrinkage in your final designs.

Precision for Delicate Designs: This method is particularly advantageous for intricate and detailed designs, ensuring that even the finest features are captured accurately.

Versatile for Various Objects: Cold silicone moulds are essential for crafting moulds from hollow objects and natural or organic materials, allowing for exceptional detail and fidelity.

High Production Capability: A single mould can produce approximately 1,500 to 2,000 cast items, making it a practical choice for medium-scale production.

-

Turnaround times can vary based on factors such as design complexity, material choice, and current production demand. However, our standard timeframes are:

Hot-mould tooling: Same-day turnaround

Silicone moulds: 1 business day

Please note that these timelines may be affected during periods of high demand. We always strive to meet deadlines as efficiently as possible.

-

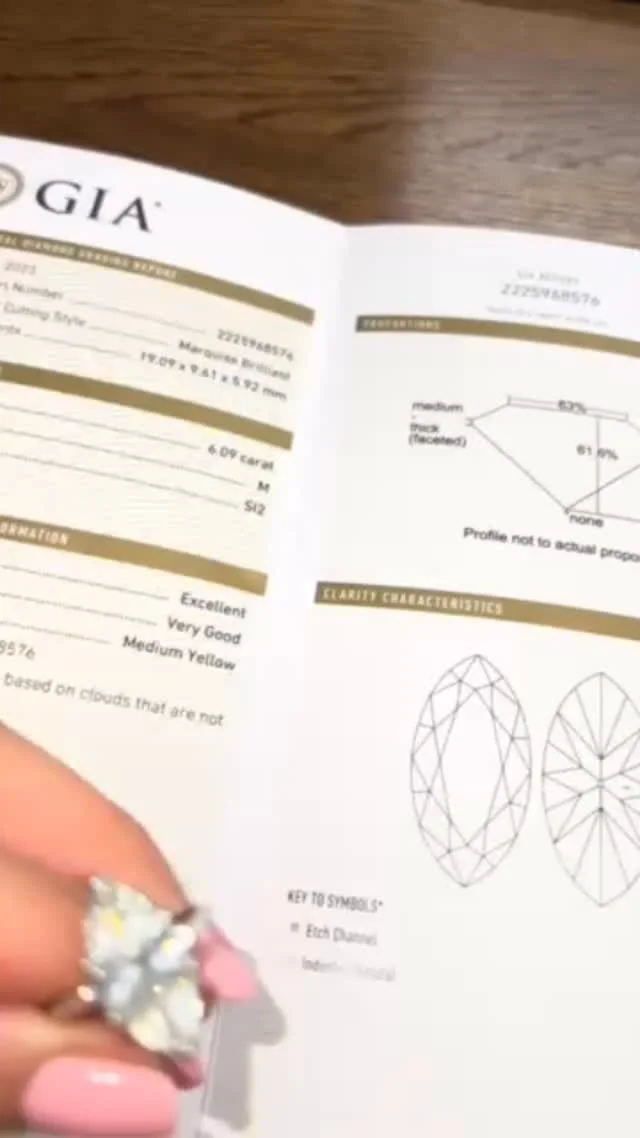

The shrinkage rate of vulcanised rubber moulds significantly impacts the final piece's dimensions, potentially leading to deviations from the intended design. Vulcanisation, a process of heating rubber with sulfur, causes the rubber to shrink as its molecular structure changes and cross-links form. This shrinkage can result in the finished product being smaller than the original mould, especially if the shrinkage rate is not accounted for in your initial design.

-

Put simply, there is no shrinkage from master to mould with a cold silicone mould. Generally, shrinkage is approximately. 1.5/2.0% from master to vulcanised mould, then a further 1.5% from mould to casting. There is no shrinkage from the master to the mould if a cold mould is used. Pink no-shrink moulds are an alternative to a cold mould if the master pattern is metal. There will always be casting shrinkage, regardless of the mould, which can be as high as 4%.

Design with Us

Design with Us

Make It Happen

Contact us today. We’d love to hear from you, whether you want to learn more about our jewellery manufacturing services or are looking for advice. We’re always happy to help.

Opening Hours

Monday-Friday 8:30 - 17:30

Saturday Closed

Sunday Closed