Our Jewellery Manufacturing Services

Unlike many jewellery manufacturers who rely on fragmented outsourcing, we provide a fully integrated, in-house production process, guaranteeing consistent quality, faster turnaround times, and uncompromising luxury-grade craftsmanship at every stage.

Jewellery Manfacturing in Hatton Garden

At House of Casting, we bring your jewellery designs to life with precision, quality, and efficiency. Whether you’re a designer, retailer, or brand looking to launch a new collection or produce bespoke pieces, our full-service jewellery manufacturing solutions are tailored to meet your unique needs.

From the initial concept to the finished product, our expert team oversees every stage of the jewellery manufacturing process. We offer advanced CAD design and 3D modelling services to perfect your designs before production, followed by precise prototyping and sampling for review and refinement. Our skilled jewellers can handle precision casting and fabrication in a wide range of precious metals, complemented by expert hand assembly. We also provide meticulous stone setting and finishing services, including polishing, plating, and thorough quality checks. Whether you require a single bespoke piece or large-scale batch production, we ensure consistent, high-quality results at every volume.

Our In-House Jewellery Manufacturing Services

Our In-House Jewellery Manufacturing Services

Your Jewellery Manufacturing Questions Answered

At House of Casting, we’re here to help you achieve the best possible results. If you can’t find the answer you’re looking for, don’t hesitate to get in touch with our team—we’re always happy to assist.

-

We provide end-to-end jewellery manufacturing services, including CAD design, 3D modelling, prototyping, precious metal casting, fabrication, stone setting, plating, polishing, and final finishing.

-

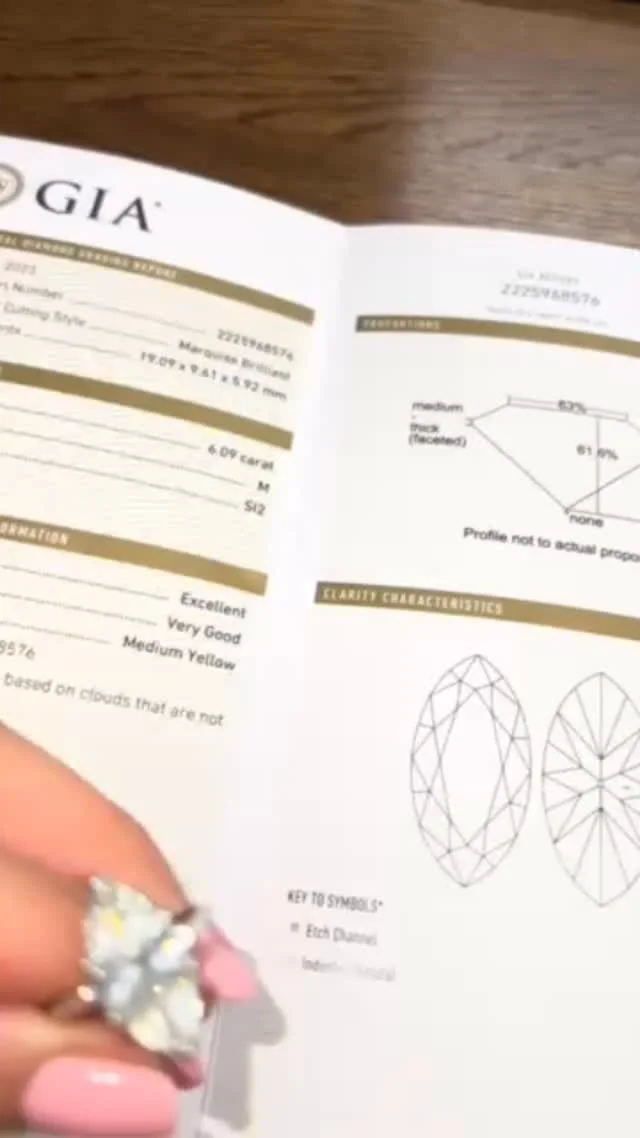

We cast and manufacture jewellery in a wide range of precious metals, including 9ct, 14ct, 18ct, and 22ct gold (yellow, white, and rose), platinum, palladium, silver, as well as alternative metals like titanium, brass, and bronze.

-

Absolutely. We accept CAD files, 3D printed models, wax prototypes, or physical samples to manufacture your jewellery according to your exact specifications.

-

Our turnaround times vary depending on the size and complexity of your order. For example, if your jewellery needs to be fully finished and set with stones, please allow up to ten working days. If it only requires casting and finishing, the turnaround is typically around five working days. Small bespoke pieces are often completed more quickly, while larger production runs may take up to two weeks.

When you request a quote, our manufacturing department will advise on the lead time.

-

Yes, our expert CAD designers can help develop and refine your jewellery designs, and we offer prototyping and sampling services to ensure your final product meets your expectations.

-

Yes, we offer high-quality plating services, including gold and rhodium plating, polishing, stone setting, and other finishing touches to complete your jewellery pieces.

-

We are flexible and happy to work with both single bespoke pieces and large production orders.

Just get in touch with your requirements, and we’ll be glad to help!

-

Wherever possible, we use recycled precious metal alloys to reduce environmental impact while maintaining the highest quality standards.

-

Yes, upon request, we can provide hallmarking services through the London Assay Office for UK compliance.

Design with Us

Design with Us

Make It Happen

Contact us today. We’d love to hear from you, whether you want to learn more about our jewellery manufacturing services or are looking for advice. We’re always happy to help.

Opening Hours

Monday-Friday 8:30 - 17:30

Saturday Closed

Sunday Closed